What Happens During an Air Conditioning Maintenance Visit?

All HVAC contractors would like their customers to sign up for long term maintenance contracts during which their company goes through a checklist of maintenance tasks. The problem is, is that most homeowners are unaware of the benefits of this maintenance, and what should be covered during these visits. Most homeowners would even assume that the company performing the maintenance should do everything that would prevent a breakdown during the heat of summer and are shocked to find out that is not often the case. In this post we hope to shed some light on the issues surrounding air conditioning maintenance and hopefully better equip you in knowing what to look for when choosing a local service company.

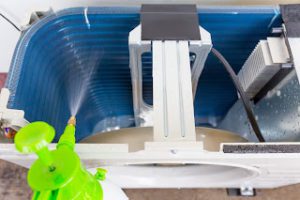

One of the most overlooked and critical aspect of maintenance for an air conditioning system is cleaning the outside condenser units coils. you wouldn’t tape cardboard to the front of your car radiator, blocking almost all airflow across it, and drive down the highway going a 100 miles per hours and expect efficient performance. Yet most Fort Worth homeowners are unaware that by not cleaning their outside units condenser coils will result in poor performance, high utility bills and sometimes catastrophic failure of your most expensive components. The condenser unit on all residential split systems is situated outside. It houses the compressor, condenser fan, and other control components. Its role is for rejecting the heat removed from the house through the median of the refrigerant that gets pumped through the system. As the compressor pumps the refrigerant through the condenser coil, air is pulled across it by the condenser fan, cooling the high pressure refrigerant in a vapor state and condensing it into a liquid before it travels inside to the evaporator coil. If airflow is blocked by dirt, dust, pollen, animal air, or other debris, it can result in loss of efficiency and more importantly, less heat transfer to the air flowing across the coil. This results in your compressor having to work harder against higher temperatures and pressures in the system, which can then lead to complete failure or burnout of the windings. Typical repair bills for this catastrophic failure can range from $2,000 upwards of $5,000 dollars, YIKES!

The moral of the story is ask if this maintenance is needed for your system. Chances are if its been a while, or this is the first you’ve been made aware of this, its time to schedule a cleaning. This can often result in additional costs on your maintenance bill. Most basic maintenance packages only cover a short check list of electrical components and their operation at this time. The whole purpose of maintenance is preventative though and a good company should look out for the interest of the homeowner and make recommendations that provide solutions to things that could arise or become an issue in the future. These items may include things like, changing a motor run capacitor, replacing a contactor, tightening electrical connections, or shielding communication or power wires from potential damage. These types of repairs are typically preventative and although your unit may seem to be running fine, they could prevent you from going through the hassle of a costly breakdown in the summer. Typical repair costs in peak season surrounding smaller electrical components and controls can run you anywhere from $139-$600. Whereas during your maintenance visit, most contractors will discount the price since the work is completed during the time they’re already at your house.

Below is a sample checklist for preventative air conditioning maintenance. A similar list should be provided to you the homeowner so you know what has been completed and why. One of the best things to do is to ask questions and gain a better understanding about your air conditioning system and how it works.

OUTDOOR UNIT CHECKLIST

![]() Inspect unit for proper refrigerant level and adjust if necessary

Inspect unit for proper refrigerant level and adjust if necessary![]() Clean dirt, leaves and debris from inside cabinet

Clean dirt, leaves and debris from inside cabinet![]() Inspect base pan for restricted drain openings—remove obstructions as necessary

Inspect base pan for restricted drain openings—remove obstructions as necessary![]() Inspect coil and cabinet—clean as needed

Inspect coil and cabinet—clean as needed![]() Inspect fan motor and fan blades for wear and damage

Inspect fan motor and fan blades for wear and damage![]() Inspect control box, associated controls/accessories, wiring and connections. Controls may include contactors, relays, circuit boards, capacitors, crankcase heat and other accessories. All control box and electrical parts should be checked for wear or damage.

Inspect control box, associated controls/accessories, wiring and connections. Controls may include contactors, relays, circuit boards, capacitors, crankcase heat and other accessories. All control box and electrical parts should be checked for wear or damage.![]() Inspect compressor and associated tubing for damage

Inspect compressor and associated tubing for damage

INDOOR UNIT CHECKLIST

![]() Inspect and clean blower assembly (includes blower housing, blower wheel and motor)

Inspect and clean blower assembly (includes blower housing, blower wheel and motor)

![]() Check blower housing for lint and debris and clean as necessary

Check blower housing for lint and debris and clean as necessary

![]() Inspect evaporator coil, drain pan and condensate drain lines. Clean as needed

Inspect evaporator coil, drain pan and condensate drain lines. Clean as needed

![]() Inspect ignition system and safety controls—clean and adjust as needed

Inspect ignition system and safety controls—clean and adjust as needed

![]() Inspect control box, associated controls, wiring and connections

Inspect control box, associated controls, wiring and connections

![]() Clean or replace air filters

Clean or replace air filters

![]() Inspect conditioned airflow system (ductwork)—check for leaks

Inspect conditioned airflow system (ductwork)—check for leaks

Although the above list will usually be covered in the basic maintenance agreement offered by most companies which can range from $50-$150 dollars depending on whats offered with it. There are still services that will incur an additional charge like cleaning the evaporator coils, outside condenser coils, or replacing components of the electrical control system. Consult with your local Fort Worth service provider about the condition of your system and what issues may need to be addressed.

If you are in the Dallas-Fort Worth area feel free to reach out to us by visiting www.topgunairtx.com or call us at (682) 214-0431. We are a local family owned and operated business that stakes our reputation on providing quality repair, installation, and service. 100% customer satisfaction is our highest priority. Given the opportunity to serve your family we guarantee not to disappoint. We take care of our people, by providing fast, reliable repair, at a fair price.