The 4 Different Types of Heating

& Air Conditioning Systems

For most people, the systems that provide central heating and air for our homes remain mysterious and complicated. The reality is the basics of heating & air conditioning/HVAC are fairly easy to understand. Buckle up and get ready to expand your HVAC knowledge!

HVAC or, Heating, Ventilation and Air Conditioning systems come in all different sizes and applications for your home or business. The whole purpose is to provide a comfortable indoor environment.

The Four Types of Heating and Air Conditioning Systems

- Heating and Air Conditioning Split Systems

- Heat Pump Systems

- Ductless or Mini-Split Systems

- Packaged Heating and Air Conditioning Systems

Heating and Air Conditioning Split Systems

It is called a split system because the components are split up into the outdoor and indoor units connected via a copper line set. On the outside is the air conditioning condenser. This house the compressor, condenser fan, condenser coil and electrical components that control its operation. The indoor units house the evaporator coil, and the blower. Usually a furnace is usually connected to this type of system. On the other hand, it might be housed in a single unit called the air handler which consists of a coil, blower, and electrical controls.

These are the most common residential type of system. They are usually the most efficient and cheapest to install for residential applications.

HVAC split systems will commonly have:

- An outdoor unit that houses the condenser coil, compressor, fan, and electrical components

- Refrigerant that circulates to and from the outdoor to the indoor units via a copper line set.

- An evaporator coil connected to a furnace or fan coil

- A blower that circulates air throughout the house and across the evaporator coil to supply air ducts.

- A single thermostat that controls the operation, or perhaps several in a zone system.

- Air ducts that carry air across the evaporator coil and out to supply air ducts in the house.

- Optional accessories for indoor air quality like Humidifiers, Air Scrubbers, or UV lamps.

Heat Pump Systems

Heat Pumps are heating and cooling systems that use the power of the compressor and circulation of refrigerant to heat or cool your home. In short they are air conditioning units that work in reverse. However, they are not appropriate for all climates. For example, the colder the average outdoor temperature is the less efficiently they work. Typically they require the installation of auxiliary heat strips.

In addition, they might also be installed in conjunction with a furnace, this system type is known as dual fuel system. This usually requires different controls to ensure your system operates most efficiently. On all but the coldest nights a heat pump takes heat from the outdoor, and condenses it in the refrigerant to bring it into your home.

With Heat Pump or Dual Fuel system you will have the following:

- A heat pump condenser that heats and cools using refrigerant

- a furnace plus the evaporator coil for conversion of the refrigerant and circulation of air

- Ductwork to move the air to and from the indoor furnace and coil in your house.

- A thermostat to control the system and maintain consistent temperature in your home

- Optional accessories for indoor air quality, or surge protection

Ductless or Mini- Split Heat Pump systems

A ductless unit has just that, no indoor ducts to move air. Installed in the zones that they heat or cool, ductless units require very little space. They are great for applications where installation of air ducts is hard or would disturb existing architecture. You can even connect as many as six indoor units to a single outdoor unit. Ductless systems are extremely efficient and operate very quietly.

They will typically have the following:

- Single outdoor heat pump condensing unit connected to the indoor units via a copper line set and control wire.

- Made up of a compact design for both indoor and outdoor units

- They utilize smaller copper line sets requiring and control wire carrying voltage and communication wire to indoor units.

- The indoor units don’t require a power source at their individual locations.

Packaged Heating & Air Conditioning Systems

A package unit is exactly what it sounds like. It contains all the components that make up a HVAC unit in a single package. Commonly installed in commercial applications, usually on roof tops of buildings.

Sometimes they are used in residential applications, installed on the roof or close to the foundation. They come in all different system configurations, from gas/electric, to heat pump with auxiliary heat.

Packaged HVAC systems include:

- The air conditioning portion or heat pump together with the evaporator and fan coil in one unit.

- Also thermostat/control interface for complete control of the system

- Optional accessories that provide better air quality for employees or inhabitants of a home.

Now you know more about each type of HVAC system and you are equipped with a greater understanding of each kind of system.

As always the primary goal for each heating & air conditioning system is to provide year round comfort in your home or business. With a good working knowledge of each type and an understanding of your specific needs you will be better equipped to select a system that works best for you.

Don’t underestimate the value of a quality HVAC installation by a reputable HVAC company. A quality installation will always ensure that you get the kind of system performance and longevity that you expect.

And to make sure that your investment in your home comfort system remains efficient and reliable for years to come, remember to schedule regular annual maintenance for your heating and cooling system.

Efficiency

Efficiency

2. Check to see if your outdoor unit is running. Chances are, if this unit isn’t running you won’t be getting cool air. Your central heating and air conditioning unit is made up of different components. Residential a/c systems are usually called split systems. The outdoor unit houses your compressor and condenser fan motor. If the unit is dead, but you hear a humming sound coming from it. Check the breaker at main panel to ensure you have power going to the unit. Chances are most times, a capacitor has gone out on it. pull your service disconnect to kill power to condenser and inspect the condition of the capacitor (a silver cylindrical object in the control panel of condenser.) often times you can determine if its bad if it appears to be bulged out at the top. Other ways of testing involve a special meter designed to read capacitance, measured in mFd. When in doubt, change it out. Other causes of the outdoor unit not working are; a burned out condenser fan motor (intermittent, or non-functioning completely) a bad

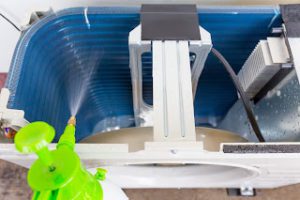

2. Check to see if your outdoor unit is running. Chances are, if this unit isn’t running you won’t be getting cool air. Your central heating and air conditioning unit is made up of different components. Residential a/c systems are usually called split systems. The outdoor unit houses your compressor and condenser fan motor. If the unit is dead, but you hear a humming sound coming from it. Check the breaker at main panel to ensure you have power going to the unit. Chances are most times, a capacitor has gone out on it. pull your service disconnect to kill power to condenser and inspect the condition of the capacitor (a silver cylindrical object in the control panel of condenser.) often times you can determine if its bad if it appears to be bulged out at the top. Other ways of testing involve a special meter designed to read capacitance, measured in mFd. When in doubt, change it out. Other causes of the outdoor unit not working are; a burned out condenser fan motor (intermittent, or non-functioning completely) a bad  3. A dirty condenser coil can cause the compressor to go off on thermal overload. This condition is caused by lack of routine maintenance. be sure to have your A/C system serviced at least every year or two. Part of this maintenance should include washing the condenser coils on your air conditioning systems outdoor unit.

3. A dirty condenser coil can cause the compressor to go off on thermal overload. This condition is caused by lack of routine maintenance. be sure to have your A/C system serviced at least every year or two. Part of this maintenance should include washing the condenser coils on your air conditioning systems outdoor unit.